|

|

|

|

|

| |

BGA,

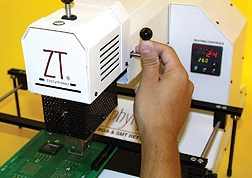

CSP & SMT Alignment, Placement, Preheat & Reflow at the Bench

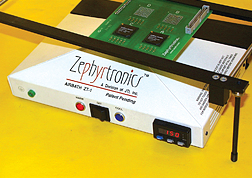

ZT-7 BGA, CSP and SMT HOT AIR REFLOW CENTER |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

NASA & ZEPHYRTRONICS EXPLAIN HOW TO QUICKLY & EASILY

ALIGN & PLACE BGA’s & CSP’s PRECISELY TO PADS IN SECONDS!

|

|

|

| |

|

|

In the early

1990’s, the engineers at Zephyrtronics cleverly had the foresight to resolve the issue of placing BGA’s to the PCB pads. Their patented invention and method, now used successfully and repeatedly by thousands of engineers and technicians around the world, makes aligning the BGA component to the BGA pads:

1) Easy to Perform. (Little Skill Required)

2) Quick to Perform. It takes less than one minute!

3) Accurate & Repeatable Placement

4) Inexpensive and Kind to Your Budget!

Our patent-protected Zephyrtronics BGA Alignment Template Cube Invention eliminates the need for expensive so-called “split-beam” vision machines, cameras and monitors, all of which (by the way) must be continuously calibrated.

Below are photographs from Zephyrtronics

and from NASA in a five step process for

aligning and reflowing the BGA to the PCB pads.

|

|

|

|

|

STEP

1:

Insert the Patented Alignment Cube into Corresponding, Non-Heated Nozzle. Activate ZT-7’s Vacuum to Secure Cube.

|

|

|

|

|

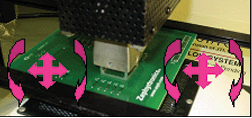

STEP 2:

Lower “Z” Axis of ZT-7 To Where Alignment Cube Hovers Directly Over (NASA Recommends About 1mm Above) the Targeted BGA Pads on the PCB Below.

|

|

|

|

|

STEP 3:

“Align the PCB’s pads for the targeted BGA to the Alignment Tool by adjusting the ABC-1 Circuit Board Cradle as necessary.”

---NASA, 2004

Photo Courtesy of NASA

|

|

|

|

|

STEP 4A:

Square and Mate Cube to Outside Perimeter of BGA Pads. The Nozzle’s X, Y and Theta are Now Precisely Relationed to Targeted BGA Pads! Cube Temporarily “Holds Place” for the BGA. Raise “Z” Axis, Deactivate Vacuum Releasing Cube.

|

|

|

|

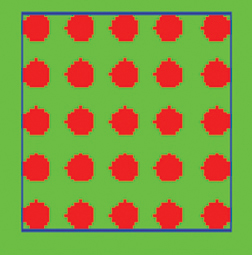

STEP 4B:

That’s right! You don’t need a ten-twenty thousand dollar “split-beam” vision alignment unit to accurately place BGA’s and CSP’s (micro BGA’s) to your PCB pads!

In fact, NASA explains the simplicity this way: “ The alignment process is completed when the solder pads are just hidden on all directions. The drawing (on the left) shows what a properly aligned 5 x 5 BGA would look like. The solder pads (red) are just contained the Alignment Tool outline (blue).”

--NASA,

2004.

Graphic Illustration Courtesy of NASA from NASA Report Describing Zephyrtronics patented BGA Alignment Invention & Method.

|

|

|

|

|

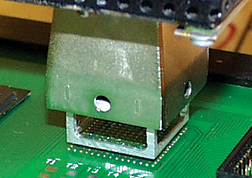

STEP 5:

Insert Your BGA/CSP into the Now-Aligned Nozzle Where the Cube Had Been. Activate Vacuum to secure BGA. Lower “Z” Axis and Nozzle Down to the Substrate. Release Vacuum. Your BGA is Positioned on to Corresponding Pads! You are now ready to reflow your BGA with your Zephyrtronics ZT-7 System. How easy is that?

|

|

|

|

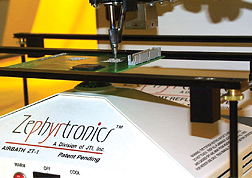

HOW TO RE-DRESS BGA & CSP PADS WITHOUT

THE USE OF HOT IRON & WICK!

|

|

|

|

|

STEP 1:

BGA removal requires cleanup as unequal solder deposits remain at vacated site. After IC removal, slide the “Y” Axis of ZT-7 back out of way, apply flux to pads. Preheat bottom of PCB at 150°C with AirBath.

|

|

|

|

STEP 2 (OPTION “A”):

After a brief preheating/soaking, use a heated DeSoldering Tool with a “soft tip-pad interface” and suck up excessive solder from pads. Preheating allows a lower, safer temp for DeSoldering.

|

|

|

STEP 2 (OPTION “B”):

Melt LowMelt® DeSolder into residual solder at pads. Remove all solder with either a foam swab or a “Solder Sucker”.

|

|

|

STEP 3:

Switch off ZT-7 and AirBath. Gently clean site with a foam swab and a Non-Flammable Flux Remover. Inspect. (Notice? No Wick!)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

©1996 - 2011, 2012, 2013, 2014-2022 Ameritronics®. All rights reserved.

The information and all images you receive online from Ameritronics® is protected

by the copyright laws of the United States. The copyright laws

prohibit any copying, redistributing, retransmitting, or repurposing

of any copyright-protected material. Ameritronics® is the registered

trademark property of JTI, Inc. "Zephyrtronics" and "Zephlux"

and "ZeroLead" and "Zero Balling" and "Zero Residue" and "Post

Cooling" and "PostCooler" and "AirBath" and "Quatro" and "Full Metal

Jacket" are the protected trademark property of JTI, Inc.

Revised for

April 18, 2016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Click link below to return to the top of the page |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

HOW TO ALIGN, PLACE AND SOLDER BGA'S? |

|

|

|

|

|

|

|

|

|

|

| |

|

|

PCB,

SMD, BGA Rework & Prototyping

AirBath,

SMD Rework

Stations,

Hot Air

Pencil Soldering,

BGA Rework

Stations,

CSP Rework

Stations,

Preheating

Systems,

PCB

Preheaters,

Pre-Heat

SMT / SMD,

Low Temp Rework,

SMT

DeSoldering Tools,

Vacuum

Pickup Tools,

Circuit

Board Holders,

PCB

Fixtures,

Board

Cradles,

Rework

Solder Paste,

No-Clean

Solder Paste,

Low Melt®

De-Solder Wire,

DeSolder

Wire,

Hot Air

Rework Stations,

Fume

Extractors,

SMT Dental

Probes,

SMT-SMD

Rework Kit,

BGA Rework

Kit,

LMK Kit,

BGA

Re-Balling Kit,

SMD

Tweezers,

Power Palm

Plunger

How To Work With SMD's, CSP's, BGA's &

QFN's

How To -

BGA Alignment:

How To -

SMT Rework:

How To - PCB Preheating,

How To -

BGA & CSP Rework:

How To -

Quickly Solder SMD Packages Effectively:

How To -

CSP Alignment;

How To -

Lead-Free Rework;

How To -

SMD Removal Economical;

How To -

SMD Removal Professional:

How To -

Hot Air Pencil / AirPencil Soldering;

How To -

SMD Quick Chip Removal;

How To -

BGA Re-Balling;

How To -

Rework PLCC - QFP, QFN, LCC, SOIC, Sub Shielded SMD, TSOP:

How To -

Solder & Rework Ceramic Capacitors:

How To -

Solder & Rework Glass Diodes

PCB

Soldering,

De-Soldering

Soldering

Accessories,

Solder

Wire,

No-Clean

Solder Wire,

Soldering Wire

Dispenser,

Solder

Paste,

Lead-Free

Solder Paste,

Flux,

Solder

Paste Dispensers,

LowMelt®

DeSolder Wire,

De-Solder

Wire,

Soldering

Irons,

Digital

De-Soldering,

Soldering

Tips,

Thru-Hole

DeSoldering Tools,

Desoldering

Tip,

Tips for

Desoldering,

De-Solder

Wick,

Smoke

Extractors,

Fume

Extractor Filters,

Carbon

Activated Filters,

SolderMill™,

Pre-Heating

Systems,

Preheat

Thru-Hole,

PCB

Pre-Heating,

Flux

Solvent,

How To - Connector Rework;

How To -

PC/104 Soldering and Rework;

How To -

Thru-Hole / Through Hole Desolder / De-Solder;

How To -

Low Melt® Desolder Wire;

How To-

Stop Lifting Pads;

How To-

Desolder / De-Solder Heavy Ground Planes;

How To -

Lead-Free Soldering and De-Soldering;

Preheaters

for Lead-Free Rework and Soldering

Dispensing, Solder Paste, Liquids & Fluids

Dispensing

Systems,

Dispensing

Syringes,

Dispensing

Barrels,

Tapered

Tips,

Blunt

Needles,

Stainless

Steel Needles,

Dispensing

Needles,

Industrial

Needles,

Dispensing

Tips,

Dispensing

Accessories,

Solder

Paste in Syringe,

Lead-Free

Solder Paste in Syringe,

Paste Rack™

Solder Paste Holder,

Dispensing

Supplies,

Power Palm

Plunger,

Manual

Dispensing,

Automatic

Dispensing

Laboratory &

Bench Supplies & Tools

SMD Solder

Paste,

Lead-Free

Solder Paste,

Solder

Wire,

LowMelt®,

No-Clean

Flux,

BGA Flux,

Rework Tack

Flux,

Non-Flammable Flux Remover,

Inspection

Equipment,

Magnification Equipment,

Magnifying

Work Light,

ESD

Magnifier,

Pen Vac,

SMT

Tweezers,

Fume

Extraction,

SMD

Tweezers,

PC Board

Fixtures,

Hot Air

Tips,

AirTips,

Replacement

Soldering Sponges,

Iron Plated

Soldering Tips,

Art

Conservation Hot Air Tools,

Foam Swabs,

Anti-Static

Foam Swabs,

Thru-Hole

Brushes,

LMK Rework

Kits |

|