|

|

|

|

|

|

|

|

|

|

|

|

|

|

PlayStation ® Repair: Your Solution for GPU, CPU, BGA, SMT & CSP Rework, Reflow, Repair & Reballing

PlayStation® Repair Made Easy

PlayStation Repair System

Soldering, De-Soldering & ReBalling the GPU, CPU on the PlayStation® Console Boards

|

|

|

|

|

|

|

|

|

|

|

Understanding the GPU, CPU, Memory Chips

and Ball Grid Arrays (BGA's):

Q: What are

these chip packages that Microsoft®

and Sony®

call the GPU, the CPU, and the Memory

Chips? And why do they look so different

from other components?

A: These are electronic chips that are

packaged in what are called Ball Grid

Array formats (BGA's). They are a

relatively new form of Surface Mount

Devices (SMD) and are similar to other

components in that they have an

integrated circuit (die) within the

package and that they have connections

to be soldered. However, instead of

leads at the side of the chip, the

connections are balls underneath the

chip (See Below):

Above Left: Bottom Side of a QFP Surface

Mount Chip with the leads at the side

for soldering to the PCB.

Above Right: Bottom Side of a Ball Grid

Array (BGA) Chip with solder spheres

(balls) at the bottom for soldering to

the PCB.

Many of the chips on the XBOX 360® and

PlayStation® Printed Circuit Boards are

packaged in the BGA format shown above

including the GPU, CPU and Memory Chips.

Indeed, most consumer electronic PCB's

today incorporate more and more BGA

style chips as they are more robust in

construction and have faster gate speed

for processing.

Once the BGA is placed and soldered onto

the PCB, you can no longer "see" the

connections (balls) as they are

underneath the chip and no longer

visible to the eye.

Finally, the XBOX and PlayStation® PCB's

components are all soldered to the pads

with lead-free solder, not the

traditional solder that everyone is

familiar with. Lead-free solder requires

higher than traditional temperatures

which makes preheating the PCB

imperative.

Good News! Believe it or not, BGA's are

surprisingly easy to remove and replace

with the right equipment, the proper

procedures. And Zephyrtronics has built

into the popular ZT-7 System so many

great features including effective

preheating of those lead-free solder

joints so as to make your job now much

easier to perform.

|

|

|

|

|

|

|

Repairing

the wildly popular Sony®

PlayStation®

printed circuit board (PCB) is now

easier than ever with the

ZT-7 Soldering

Benchtop System.

The ZT-7 System makes either 1.) just

re-soldering chips; or 2.) de-soldering

and removing a GPU, CPU or Memory Chips

and then replacing and re-soldering them

back to the PCB.

The ZT-7 is affordable, has 15 years of

proven performance, is made in the U.S.

with a 2-year limited warranty.

Don't be fooled by IR systems that

might repair the PCB temporarily, but

can actually do more harm than good to

the board and chips. You want complete

reflow of the entire ball of solder

(inside and outside) on every

connection, and not what is called

"tangential reflow" that will reopen

when the board flexes, especially when

the XBox® is being used again.

Video Comparisons

& Demonstrations: 4 Methods of

Preheating & Solder Reflow

illustrates the advantages of forced

convection and why it is the PCB

industry standard worldwide. |

|

|

|

PCB Fixtures Must Be Independent

from both lower preheaters and from

upper reflow heaters.

If

one is repairing a lot of PCB's, speed

is important. Waiting for big PCB's

(XBox 360) to preheat and later to cool

down for a long time before moving on to

another PCB wastes time, money and

profit.

An

Independent PCB Holding Fixture

is simply essential for reworking PCB.

Save time and money. Learn why:

Video: The ABC's

of PCB Holding Fixtures. By

the way, the ZT-7 System is equally

effective for repairing the

XBox 360.

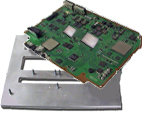

Below is a

PlayStation®

PCB populated with large GPU and CPU

chips with metal tops and lead-free

solder balls that require effective,

forced convection (hot air) preheat to

achieve proper soldering of all balls

and pads under the chips.

Not Just for Game Consoles, the

ZT-7 can be a moneymaker for repairing

smartphones, tablets, laptops, plasma

TV's, lab prototyping and rework/repair. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

At

left is one of the two large

processors used on the PlayStation®.

The high metal content on top of the

chip makes it very difficult to

remove, reball, replace and

re-solder without damaging the chip.

It is imperative that both the PCB

and chip are carefully preheated

first, preferably with hot air, so

soldering is not made at excessively

high temps. Preheat temps should

never exceed 170°C.

This is where IR systems fail. |

|

|

|

One of the PlayStation®

BGA's Shown Above |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Beware! Some "repair stations" have very

ineffective upper heaters requiring the entire

PCB be preheated underneath to over 200°C for

over twenty minutes! Worse, the

manufacturers of these "machines" advise users

to cover chips with foil when using them. Are

they crazy? This nonsense is prohibited by

reputable PCB labs and repair companies.

PCB

repair done on the cheap or with high

temperatures will fail, if not immediately, not

long afterwards. Semiconductors begin to degrade

at 260°C and they degrade permanently.

Helpful Rework

Guide:

Good enough for NASA and easy enough for

PlayStation®

repair! Click for more details on the

ZT-7 Hot Air Station.

Each ZT-7 ships with a helpful, detailed owners

manual plus a 39-page report by NASA with nearly

300 photographs filled with technical tips and

techniques, and a step-by-step illustrated

process guide. Easy to operate with

digital closed-loop programmable (31 storable

profiles) temperature control, digital countdown

timing, bottom-side preheat and thermal ramping

for high quality. |

|

|

|

Used by NASA to place and solde

high-reliability I.C.'s on the two successful

Mars Rovers and Curiosity missions, the

ZT-7 is used by

Fortune 500 electronic campuses around the world

since 1998.Why is this important? Because our

so-called competitors have introduced machine

after machine only to obsolete them and then

re-introduce another machine leaving their poor

customers without service or replacement parts!

The ZT-7, on

the market for 16 years has a 2-year limited

warranty.

A

Warning from NASA About IR Rework Systems:

"Hot

plates and infrared pre-heaters are not

recommended...The reason that they should

not be used is that the thermal reaction times,

energy transfer rates and efficiency are never

consistent."

For more specs, technical info and product

details about our popular XBox® or PlayStation®

hot air repair stations, click the full webpage

for the

ZT-7 Hot Air BGA & SMT PCB

Center. Or call us at

our Los Angeles factory Mon-Fri 8-6PM (Pacific)

at (909) 865-2595 or e-mail

sales@ameritronics.com.

Let us help. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ZT-7-PSR REWORK COMPREHENSIVE SYSTEM

|

|

Description

|

Item |

Price |

|

|

The

ZT-7-PSR

System

Comprehensive BGA &

SMT

Hot Air Bench Top

Reflow

System

Includes:

The

ZT-7-MIL (shown above)

and

The

ZT-1-BGS-DPU

AirBath

The

ABC-1 Adjustable

Board Cradle

ZT-7-PSK Benchtop

Supply Kit Includes the

42.5mm X 42.5mm BGA Nozzle for the GPU &

CPU and Your Soldering & DeSoldering

Supplies

|

ZT-7-MIL

ZT-1-BGS-DPU

ABC-1

ZLK-PS

|

$5,950

LIMITED

TIME

OFFER!

$4,905

|

|

|

The

ZT-7-PSR-ZF

System

Comprehensive BGA & SMT

Hot Air Bench Top

Reflow System

Includes:

The ZT-7-MIL (shown

above)

and

The

ZT-1-BGS-DPU

AirBath

The

ABC-XYZ Adjustable

Board Cradle

ZT-7-PSK Benchtop

Supply Kit Includes the

42.5mm X 42.5mm BGA Nozzle for the GPU &

CPU and Your Soldering & DeSoldering

Supplies

|

ZT-7-MIL

ZT-1-BGS-DPU

ABC-1

ZLK-PS

|

$6,300

LIMITED

TIME

OFFER!

$5,285

|

|

Playstation ZeroFlex™ Template

Thick, Machined Metal Plate With

Reciprocal Studs for PCB Holes

Thick Metal Plate Prevents PC Board

Flexing During Rework

Openings Permit PCB Quicker & More

Uniform Preheat From Below

Works With

ABC-XYZ Board

Cradle

(Note: ZeroFlex™ Template is Included

In ZT-7-PSK Kit)

|

ZT-7-ZF-PS |

$125

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

©1996 - 2011, 2012, 2013, 2014 Ameritronics®. All rights reserved. The

information you receive online from Ameritronics® is protected by

the copyright laws of the United States. The copyright laws prohibit

any copying, redistributing, retransmitting, or repurposing of any

copyright-protected material. Ameritronics® is the registered

trademark property of JTI, Inc. "Zephyrtronics" and "Zephlux"

and "ZeroLead" and "Zero Balling" and "Zero Residue" and "Post

Cooling" and "PostCooler" and "AirBath" and "Quatro" and "Full Metal

Jacket" are the protected trademark property of JTI, Inc.

Revised for

November 21, 2016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PCB,

SMD, BGA Rework & Prototyping

AirBath,

SMD Rework

Stations,

Hot Air

Pencil Soldering,

BGA Rework

Stations,

CSP Rework

Stations,

Preheating

Systems,

PCB

Preheaters,

Pre-Heat

SMT / SMD,

Low Temp Rework,

SMT

DeSoldering Tools,

Vacuum

Pickup Tools,

Circuit

Board Holders,

PCB

Fixtures,

Board

Cradles,

Rework

Solder Paste,

No-Clean

Solder Paste,

Low Melt®

De-Solder Wire,

DeSolder

Wire,

Hot Air

Rework Stations,

Fume

Extractors,

SMT Dental

Probes,

SMT-SMD

Rework Kit,

BGA Rework

Kit,

LMK Kit,

BGA

Re-Balling Kit,

SMD

Tweezers,

Power Palm

Plunger

How To Work With SMD's, CSP's, BGA's &

QFN's

How To -

BGA Alignment:

How To -

SMT Rework:

How To - PCB Preheating,

How To -

BGA & CSP Rework:

How To -

Quickly Solder SMD Packages Effectively:

How To -

CSP Alignment;

How To -

Lead-Free Rework;

How To -

SMD Removal Economical;

How To -

SMD Removal Professional:

How To -

Hot Air Pencil / AirPencil Soldering;

How To -

SMD Quick Chip Removal;

How To -

BGA Re-Balling;

How To -

Rework PLCC - QFP, QFN, LCC, SOIC, Sub Shielded SMD, TSOP:

How To -

Solder & Rework Ceramic Capacitors:

How To -

Solder & Rework Glass Diodes

PCB

Soldering,

De-Soldering

Soldering

Accessories,

Solder

Wire,

No-Clean

Solder Wire,

Soldering Wire

Dispenser,

Solder

Paste,

Lead-Free

Solder Paste,

Flux,

Solder

Paste Dispensers,

LowMelt®

DeSolder Wire,

De-Solder

Wire,

Soldering

Irons,

Digital

De-Soldering,

Soldering

Tips,

Thru-Hole

DeSoldering Tools,

Desoldering

Tip,

Tips for

Desoldering,

De-Solder

Wick,

Smoke

Extractors,

Fume

Extractor Filters,

Carbon

Activated Filters,

SolderMill™,

Pre-Heating Systems,

Preheat

Thru-Hole,

PCB

Pre-Heating,

Flux

Solvent,

How To - Connector Rework;

How To -

PC/104 Soldering and Rework;

How To -

Thru-Hole / Through Hole Desolder / De-Solder;

How To -

Low Melt® Desolder Wire;

How To-

Stop Lifting Pads;

How To-

Desolder / De-Solder Heavy Ground Planes;

How To -

Lead-Free Soldering and De-Soldering;

Preheaters

for Lead-Free Rework and Soldering

Dispensing, Solder Paste, Liquids & Fluids

Dispensing

Systems,

Dispensing

Syringes,

Dispensing

Barrels,

Tapered

Tips,

Blunt

Needles,

Stainless

Steel Needles,

Dispensing

Needles,

Industrial

Needles,

Dispensing

Tips,

Dispensing

Accessories,

Solder

Paste in Syringe,

Lead-Free

Solder Paste in Syringe,

Paste Rack™

Solder Paste Holder,

Dispensing

Supplies,

Power Palm

Plunger,

Manual

Dispensing,

Automatic

Dispensing

Laboratory &

Bench Supplies & Tools

SMD Solder

Paste,

Lead-Free

Solder Paste,

Solder

Wire,

LowMelt®,

No-Clean

Flux,

BGA Flux,

Rework Tack

Flux,

Non-Flammable Flux Remover,

Inspection

Equipment,

Magnification Equipment,

Magnifying

Work Light,

ESD

Magnifier,

Pen Vac,

SMT

Tweezers,

Fume

Extraction,

SMD

Tweezers,

PC Board

Fixtures,

Hot Air

Tips,

AirTips,

Replacement

Soldering Sponges,

Iron Plated

Soldering Tips,

Art

Conservation Hot Air Tools,

Foam Swabs,

Anti-Static

Foam Swabs,

Thru-Hole

Brushes,

LMK Rework

Kits |

|

|

|

|

|

|

|

|

|

|

|

|

|